- WhatsApp: +86 13606526028

- Email: contact@utien.com

Shipping costs can greatly affect your business's profits. Compress packaging machines help by making packages smaller and saving space. These machines press out air to shrink bulky items by 50% or more. Smaller packages mean lighter shipments, which cut shipping costs.

Companies using these machines often notice:

Less material waste because of better packaging.

Yearly savings up to $1 million for big manufacturers.

Using this technology can simplify work and save a lot of money.

Compress packaging machines are great at making big items smaller. They push out air and seal packages tightly, cutting size by up to 50%. This helps you fit more items in each shipment, saving space and lowering shipping costs.

Smaller packages mean less empty space. This reduces the need for extra materials like bubble wrap or fillers. It saves money and helps the environment by creating less waste.

These machines also make sure every package is sealed well. This keeps items safe during shipping and makes customers happy.

Good storage is important to save money in shipping. Compress packaging machines shrink items, so you can store more in the same space. Smaller packages let you stack and organize better, leaving room for other tasks.

Faster packing because of automated machines.

Fewer workers needed, cutting costs.

Fewer mistakes, keeping products safe.

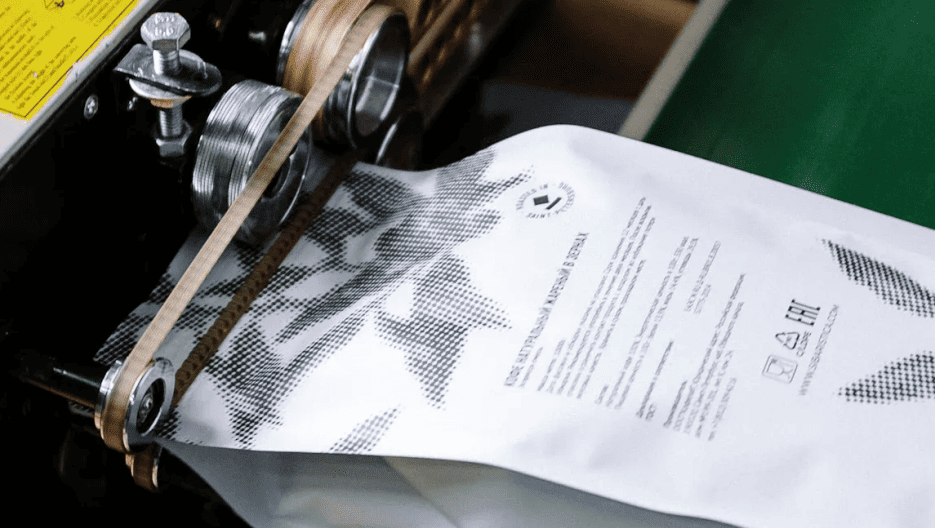

Shrink wrapping machines, a type of compress packaging machine, make work easier. They handle tasks faster, helping during busy times without losing quality.

Compress packaging machines help lower shipping costs by making packages smaller. Smaller packages weigh less and take up less room, which means cheaper shipping.

Feature | What It Does |

Less empty space | Cuts down on unused space, saving shipping money. |

Smaller boxes | Fits items better, using less material. |

Eco-friendly | Needs fewer fillers, helping the planet. |

Saves money | Boosts work speed with fewer workers, handling busy times easily. |

Using compress packaging machines helps save money and improve shipping. They are a smart choice for businesses wanting to work better and spend less.

Compress packaging machines let you change how much they compress. This helps protect fragile items while shrinking bulky ones to save space. You can adjust the pressure to match different materials, making every shipment just right.

Tip: Changing settings lets you pack soft or hard items safely.

These settings also make work easier by using one machine for many tasks. This reduces the need for extra equipment, saving time and money.

Compress packaging machines work with many types of materials. They can handle polypropylene, PET, and laminates, adapting to different sealing needs.

Material Type | Sealing Options | Works Best For |

Polypropylene | Heat or cold sealing | Many kinds of products |

PET | Special sealing methods | Items sensitive to moisture |

Laminates | Flexible sealing choices | Various packaging requirements |

This flexibility helps your machine fit into your current system. Picking the right materials improves seals and keeps items safe during shipping.

New compress packaging machines are built to save energy. They use smart technology like compressed air motors to work better with less power.

Air motors use less energy by working efficiently.

Smaller motors still get the job done, saving power.

Smart controls manage systems to cut energy costs.

Energy-saving machines lower costs and help the environment. Using less energy supports a greener supply chain while keeping performance high.

Compress packaging machines are important for online stores and retail. These businesses ship many items, so saving space and money is key. By making packages smaller, these machines let you store and ship more items in less space. This lowers shipping costs and makes work smoother.

Benefit | What It Means |

Space Savings | Smaller packages save room for storage and shipping. |

Increased Efficiency | Speeds up packing, helping with faster delivery. |

Long-term Savings | Cuts costs by working better and reducing damaged products. |

In online shopping, fast delivery and happy customers matter most. Compress packaging machines keep items safe while shipping. They also use less packing material, cutting waste and helping the planet.

In factories and warehouses, these machines make packing easier. They speed up work by automating tasks, helping meet deadlines without losing quality. They also lower labor costs by needing fewer workers.

Saving energy with smart power use.

Protecting items from damage or dirt.

Making packages look better for customers.

Cutting shipping costs with smaller packages.

Adding these machines to your work saves time and money. They can handle many materials, so they fit into your current system easily.

Food and drink companies gain a lot from these machines. They keep food fresh by sealing it tightly and stopping contamination. They also shrink big items like snack bags, making storage and shipping easier.

For foods that spoil quickly, these machines keep them safe while traveling. This means less waste and happier customers. Using less packing material also helps the environment, which is very important today.

By using compress packaging machines, you can save money, work faster, and meet safety rules while being eco-friendly.

Choosing the right machine is very important. First, think about the materials you use most. Machines that work with many materials, like polypropylene or laminates, are more useful. Also, check the size and weight of what you pack. A machine with adjustable settings can handle both big and delicate items.

Follow these steps to choose wisely:

Make a plan listing your packaging needs and goals.

Look for machines that fit your needs and compare features.

Buy from trusted sellers to get good-quality machines.

Test the machine with your materials before buying it.

The right machine helps you save money and work faster.

Installing and training are key for smooth work. Ask your seller to help set up the machine and connect it to your system. Test it first to make sure it works well.

Training your team is just as important. Teach them how to use the machine safely and handle emergencies. Create lessons to improve problem-solving skills. Offer regular training to keep everyone updated on new features.

SOP Title | What It Covers |

Operator Training SOP for Packaging Equipment | Steps to train workers on using packaging machines. |

SOP for Packaging Line Certification | Rules to check if packaging lines work well and follow standards. |

Training Checklist for Packaging Machinery SOPs | A list to ensure workers complete all needed training. |

Good training and setup make the machine work better and safer.

Taking care of your machine keeps it working well. Check it often to find problems early. Clean it regularly to stop dust from causing issues.

Make a care plan that includes:

Checking seals and settings to ensure they work right.

Replacing broken parts quickly.

Watching energy use to keep it efficient.

Tell your team to report problems right away. Fixing small issues fast avoids bigger, costly repairs. A well-kept machine works better and lasts longer.

Compress packaging machines are a clever way to save money. They make packages smaller, cutting shipping and storage costs. These machines also improve how work gets done, boosting productivity. By saving money and improving logistics, they are worth the investment.

Use compress packaging machines now to save money and work faster. They are a smart choice for businesses wanting to stay ahead in a busy market.

You can pack many things like clothes, bedding, food, and tools. These machines are great for soft or bulky items. They make storage and shipping easier by shrinking the size.

Compress packaging machines can shrink packages by 50% or more. This lets you store and ship more items in less space. It saves money and makes work faster.

Tip: Use these machines for big, fluffy items to save space.

Yes, they are eco-friendly. Smaller packages need fewer materials like bubble wrap. Many machines also use less energy, helping the planet and saving money.

Clean the machine and check seals often. Replace worn parts quickly. Make a weekly plan to inspect it. Fix small problems early to avoid big repairs.

Yes, they can handle delicate items safely. You can adjust the pressure to protect fragile things. This makes the machines useful for many products.

Utien Pack offers a full range of advanced compress packaging machines designed to meet the needs of industries like food, retail, manufacturing, and logistics. With our self-developed solutions and years of technical experience, we help businesses reduce costs, optimize storage, and improve packaging quality.

By continuing to use the site you agree to our privacy policy Terms and Conditions.